Humidity control in explosive & munition manufacturing

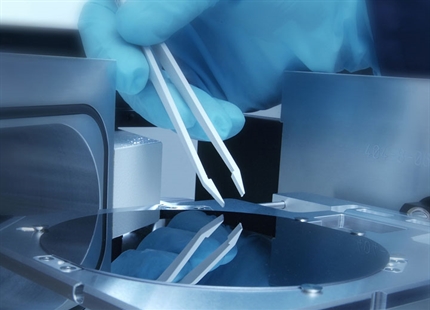

During the manufacturing of explosive devices such as munitions, fireworks or flares, uncontrolled static electrical discharge presents a high risk to the combustible materials being processed. By maintaining a humidity of 55%rH static build-up is avoided as the moisture acts as a conductor and dissipates any electrical charge generated by friction.

Thermohygrographs are used to record the temperature and humidity in explosive manufacturing facilities so that the environmental conditions munitions are produced under can be traced back and checked should a defect be identified in the field at a later date.

Both in-room and in-duct humidifiers are used in these environments but they must be ATEX explosion proof and intrinsically safe. JetSpray compressed air and water humidifiers are popular as, unlike steam humidifiers, they do not contain electric heating elements and still provide very close control over the humidity to within +/-1%rH.

Benefits of Condair humidification in the explosives industry include:

- Extensive expertise around the world with many explosive & munition industry clients

- Comprehensive product range to precisely meet customers' requirements

- Ability to provide innovative custom solutions for unusual processes

- Low energy systems to reduce operating costs and improve humidity control

- Low maintenance solutions to reduce on-going service requirements

- Comprehensive service of expert advice, design, supply, installation, commissioning, maintenance and spares supply

Use our online product selector

Get free expert advice on humidity control in ATEX environments

Free 10-point guide to cleanroom humidity control

This guide has been compiled from Condair's extensive experience across thousands of cleanroom humidity control projects.

It gives an overview of the 10 most important topics to consider when setting out on a cleanroom humidification or dehumidification project.

PODCAST: CLEANROOM HUMIDITY CONTROLLearn how to manage humidity in tightly controlled areas.

You may also be interested in...

Abattoir humidification

Humidity control for bakeries

Printing humidification

Cleanrooms & laboratories humidification

Home humidification

Spray booth humidification

Dehumidifiers for military storage

Paper & pulp production humidification

Office humidification