JetSpray compressed air & water spray humidifier

The JetSpray provides very accurate humidity control directly to a room's atmosphere using a combination of compressed air and water. A series of strategically located nozzles provide consistent humidity throughout the space.

The use of compressed air ensures very rapid moisture evaporation, without the risk of wetting or drips, and highly directional spray aerosols.

The JetSpray is available in 60L/h and 600L/h capacity models. The 600L/h model is available with on/off control or fully modulating 0-100% output for highly accurate +/-2%RH humidity control.

Self-cleaning nozzles enable the humidifier to work with any potable water quality without the need for a demineralised supply. Its fan-free design ensures robust operation in dirty, dusty industrial environments with minimal maintenance.

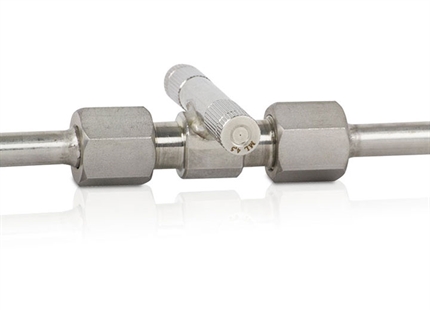

The JetSpray nozzle contains a self-cleaning mechanism that prevents blockages. Installation is easy and can be carried out by any competent HVAC contractor without the need for special tools. It incorporates standard plumbing fittings and can be supplied with stainless steel, copper or plastic pipework.

Features and benefits

- Robust self-cleaning operation ideal for industrial use

- Provides accurate and consistent humidity across an area

- Very low energy use and operating costs

- Can run on mains, softened or demineralised water

- Easy to install and operate

- 0-100% modulation for close control

Ideal for industrial environments

Get free expert advice on spray humidifiers

Free 10-point guide to specifying humidifiers

Download your 10-point guide to specifying humidifiers and get an easy-to-follow overview for planning humidifier projects.

It covers topics such as psychrometrics, product sizing, technology selection, installation considerations and hygiene management.

PODCAST: HOW TO SELECT & SIZE A HUMIDIFIERLearn how to plan a humidification project.

You may also be interested in...

JetSpray Compact low capacity air & water spray humidifier

ML Solo high pressure direct air humidifier

ML Flex high pressure direct air humidifier

ML Princess high pressure direct air humidifier