Author: Dave Marshall-George, UK Sales Director, Condair

Read the original article as it appeared in ACR News March 22

Dehumidification – a hot topic

When clients approach Condair for a drying solution, they are often surprised when our initial project research focuses as much on the required air temperature as it does the desired humidity level. Temperature and humidity are inextricably linked, but the required temperature of an area is a determining factor in dehumidifier technology selection and system design.

When water is condensed or adsorbed from its gaseous state to a liquid state, to remove it from the air, heat is produced. The two main types of dehumidifier, condensing and desiccant, both produce heat during the dehumidification process. Depending on the needs of the area being dried, the management of this heat can significantly impact the complexity, and ultimately the cost, of a project.

In order to successfully achieve the required room condition, it is vital this thermal management is properly considered and calculated alongside the removal of moisture.

The desiccant process

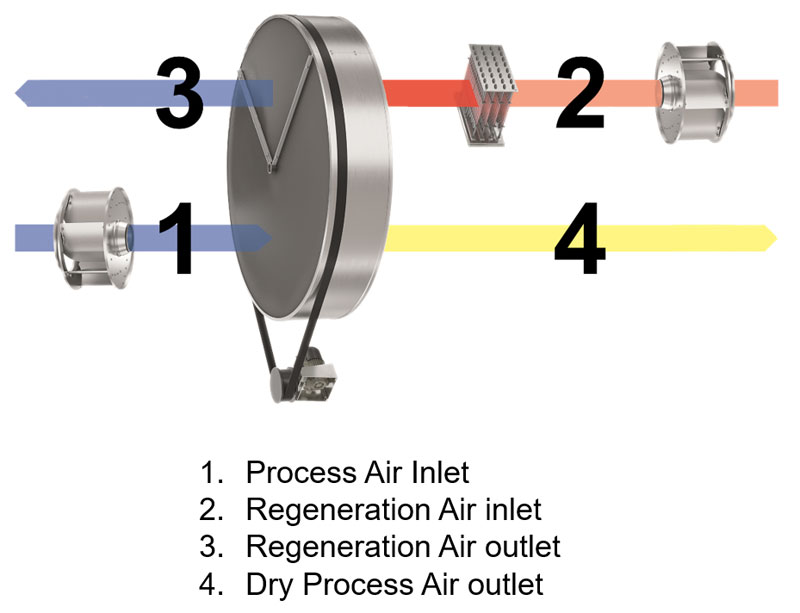

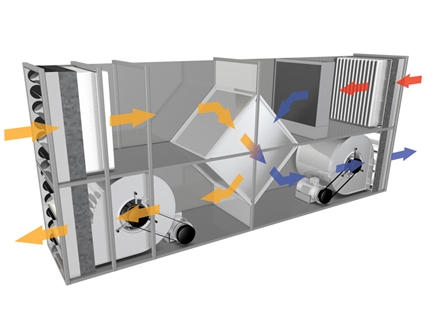

A desiccant dehumidifier removes moisture from the air by adsorbing it in a slowly turning desiccant wheel. Similar to a sponge literally soaking up water, the desiccant wheel adsorbs moisture from the air passing through it. To avoid saturation, very hot air is forced through a section of the wheel, during its rotation. This is called regeneration. The hot air has a very low relative humidity and draws water from the desiccant wheel, as it slowly rotates through the regeneration area. This hot, wet regeneration air is then vented externally, rejecting the moisture and ensuring the dehumidifier can continuously dry the air.

This process of moisture adsorption by the desiccant generates heat. For every 1kg of moisture removed, around 680W of heat is produced. Alongside this thermodynamic heating of the process air, there is also residual heat being applied to it from the regeneration area of the desiccant wheel. As the slowly turning wheel moves from the hot regeneration airflow, into the cooler process airflow, warmth is transferred. This warming effect can contribute as much as 1-3°C of heat, per gram of moisture removed, to the supply air from the wheel.

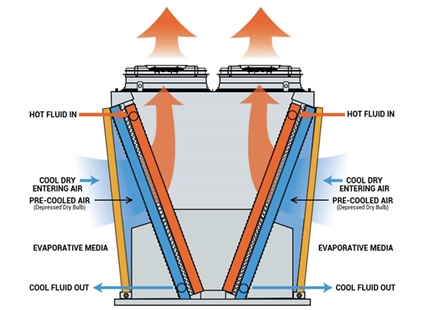

So alongside removing moisture from the air, the desiccant dehumidification process is adding considerable heat to the process airflow. To counter this, a cooling coil can to be applied to the air either after the desiccant drying process (post-cooling) or before the drying process (pre-cooling).

To put this into the context of a project, if a room has an ambient condition of 20°C and 60%RH, and the humidity needs to be reduced to 30%RH, the desiccant drying process could add between 18-21°C to the supply airflow. Around two thirds of this heat gain is from the thermodynamic process, as 4.4g of moisture per kilo of dry air is adsorbed by the desiccant. The remaining third comes from the residual heat the desiccant wheel picks up in the regeneration process. This significant increase in air temperature would, in most cases, be undesirable. So a cooling coil can be added to the dehumidifier, either by the HVAC installer or by the manufacturer. This will temper the air back down towards the ambient room temperature.

Another important thermal aspect of a desiccant project to consider is that of the regeneration airflow. To use this technology, the installation requires ducting of the very hot, wet air away from the room being dried. In situations where this isn’t possible, an alternative is to add an additional cooling coil to the regeneration airflow, cooling it down and condensing the water out to drain.

The condensing process

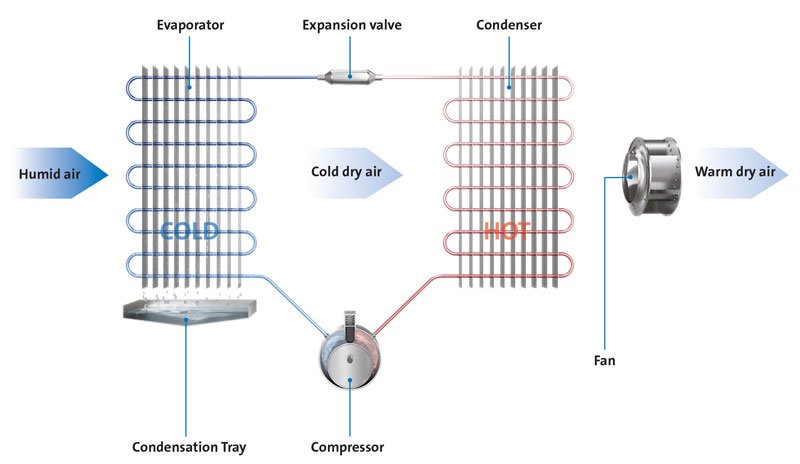

A condensing dehumidifier removes moisture from the air by creating a cold surface upon which water vapour condenses. It chills the air below its dew point, using the evaporator side of a standard refrigerant circuit. It then reheats the dried air with the hot condenser side of the circuit. The conditioned air is then supplied to the room and the condensation sent to drain.

Ambient temperature is especially important in condensing dehumidifier projects, as the lower the ambient temperature, the less efficient the process of condensation becomes. Unlike desiccant dehumidifiers, which can dry no matter what the ambient temperature is, a condensing dehumidifier is only really effective in temperatures of 20°C or more.

If the environment suits a condensing dehumidifier, the heat added during the drying process will still need to be considered in the overall system design. The same level of thermodynamic heating is present in condensing dehumidification as it is in desiccant systems. As moisture turns from vapour to liquid, heat is released, which warms the air passing through the dehumidifier. This results in the air leaving the dehumidifier, after drying, being significantly warmer than the air entering the dehumidifier.

To put this into the context of a project, if a room has 20°C and 60%RH, and needs to reduce the humidity to 50%, the heat gain to remove the moisture required could be around 7°C. This heat gain is much less than that experienced with desiccant systems, as there is no hot desiccant wheel to consider.

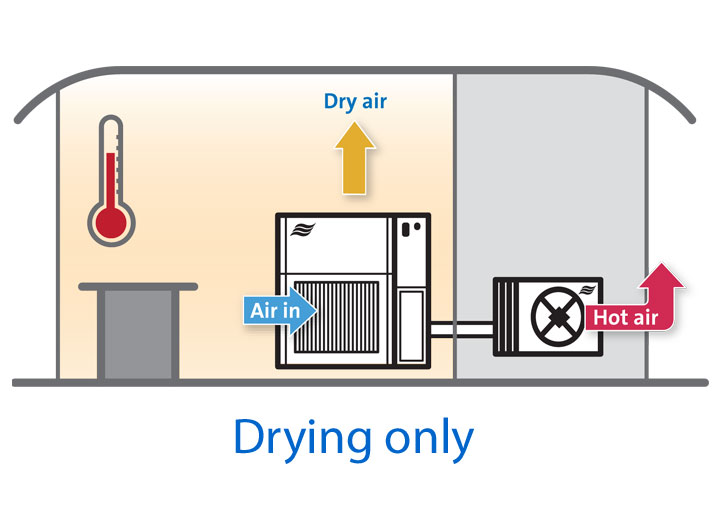

Frequently, the level of heat gain from condensing systems is low enough to not detrimentally impact the thermal comfort of an area or a manufacturing environment. Sometimes it can even be a significant benefit, if it can replace other sources of heating. However, if this thermal contribution causes an area to overheat, it can be countered with standard air conditioning systems. Splits being the most popular solution we encounter.

An alternative to adding AC, is to use a condensing dehumidifier with a remote condenser. Dehumidifiers, such as the Condair DC-N, incorporate a secondary condenser, that can eject the refrigerant circuit heat outside, similar to a split AC. If the room temperature is lower than the required level, the integrated condenser will provide heat to the room when drying. When the temperature level is reached, the external condenser is activated, avoiding any overheating of the area during the drying process.

So in summary, when setting out on a dehumidifier project, it is important to evaluate not only the required humidity level, but also the temperature of the supply air to the dehumidifier, the acceptable ambient temperature in the room and how heat from the drying process could be managed. If in doubt, always seek advice from the manufacturer. They should be able to give detailed information on the exact heat gain any dehumidifier process will provide, along with advice on options for dealing with it, to perfectly meet the client’s desired room condition across both humidity and temperature.